Death by Twinkies

Jan 26 2015

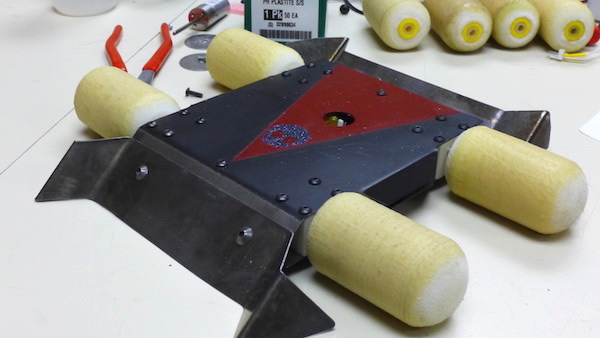

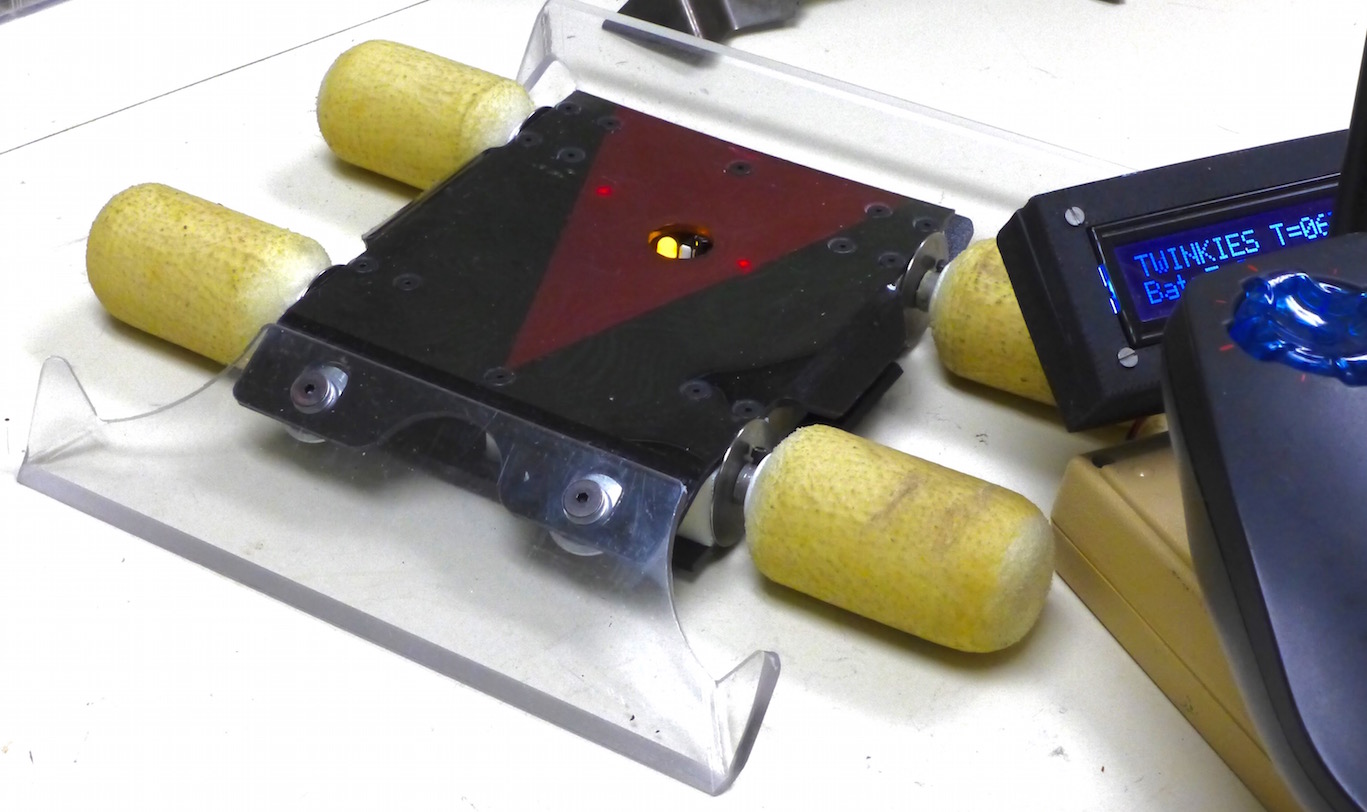

After the destruction of Dead Air by 10,000 RPM spinner DDT at 2014 Dragon Con Robot Battles I decided to try to build a very robust pushy bot that can survive both vertical and horizontal spinner attacks. This is the end result. Death by Twinkies!

Just the facts

- Body: .025" titanium

- Scoops: .025" 1095 steel heat treated to spring temper

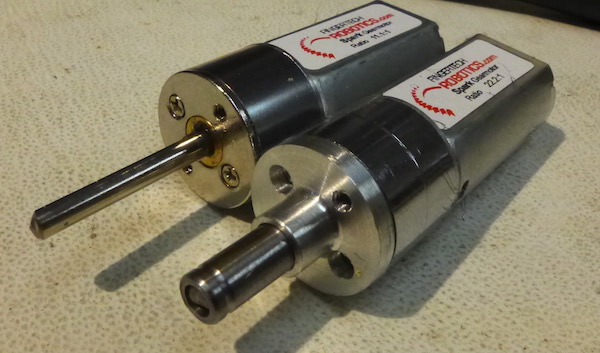

- Motors: Silver Spark 22:1

- Wheels: 2 inch foam paint rollers with 6 layers of brush-on latex

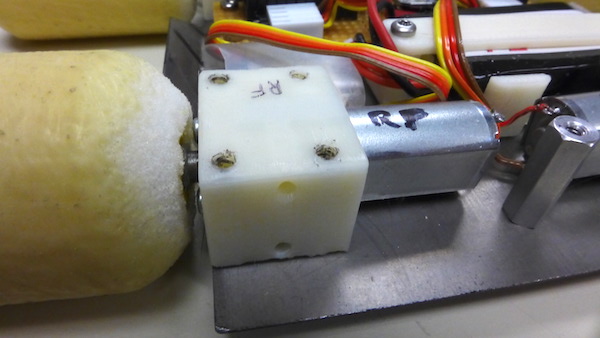

- Motor mounts: Custom 3D printed ABS

- Radio: XBee

- Controllers: Pololu Baby Orangutan

- Battery: 7.4 volt 450mAh LiPoly

- Weight: 15.5 oz

Wheels

The first thing you are probably wondering is why I put giant soft squishy foam wheels on this thing. Won€™t they be easily destroyed with even the weakest spinner? The answer is no. I actually tested their durability with a typical spinner blade attached to a 22,000 RPM die grinder. The result is in the picture below. The blade cut slots and chunks out of the foam but did not transfer any significant energy to the bot. Best of all, the damaged wheels still worked fine after all the abuse.

The 2 inch foam paint roller is coated with 6 layers of brush-on latex from Dick Blick art supply. Traction is excellent. They are attached to the motor shaft by a press fit nylon size adapter. The paint roller has a .255 inch hole. I made nylon adapters 1/2 inch long, .259 OD x .116 ID. I pressed the adapter into paint roller after coating with super glue. They slide on and off the 3mm motor shafts with hand pressure. Unfortunately I later discovered the 3mm shafts were too weak. The fix for that issue will be described later.

Body

The body consist of two identical cut and bent sheets of .025 inch titanium. The top panel has an extra hole to access the power switch and charging connector. This is the first time I worked with titanium. I cut a blank rectangle off a larger sheet with my bandsaw using a 18 tpi bi-metal blade. The blade survived. The actual cut out was done on my CNC mill with carbide end mills. I bent it with my box and pan brake. All the angles are 45 degrees. I discovered it will crack if bent 90 degrees.

Scoops

These are made of 1095 high carbon steel. I made a template with a CAD program, printed it and glued it to the steel. I used a bandsaw to cut along the template lines. Then it was drilled and bent with the box and pan brake. To make sure the bottom was straight and flush with the surface I screwed it to a piece of wood cut at 45 degrees and applied the bottom edge to a belt sander. Once I was satisfied everything was correct I heated them to 1475F then plunged in oil. After cooling they were reheated to 625F for spring temper.

To maintain floor contact the scoops are loosely attached to the titanium body so they can slide up and down. They will also go over small ridges without getting stuck.

Motor Mounts

These were designed with ViaCAD and printed with an UP! 3D printer. They also hold the covers on.

Here is the stl file in case you want to make your own. Mounting holes are for #4 screws, self taping or you can tap for 4-40 screw.

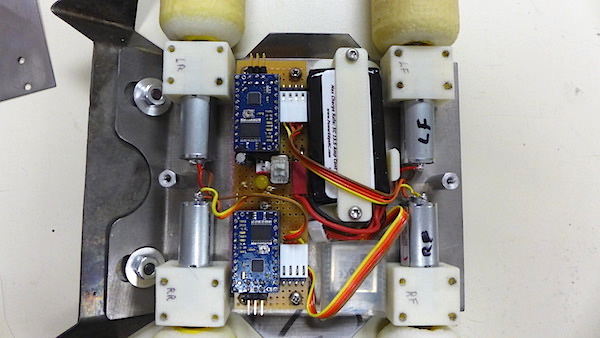

Controllers

The blue pc boards above are Pololu Baby Orangutan robot controllers. They have an AVR atmega328 microcontroller and h-bridges for 2 motors. The h-bridge is rated at 1 amp per motor continous. Since each Silver Spark motor can suck about 1.2 amps when stalled I needed 2 controllers to handle 4 motors. The XBee radio is connected to the serial input of both controllers which have identical programs. One controls the front wheels, the other the rear.

One of the controllers monitors battery voltage and state of charge and sends the data via XBee to the hand held control display. I don't have to guess how much charge is left.

Motor shaft modifications

To prove how tough this bot is I drove it off a table. To protest this abuse one of the 3mm motor shafts bent slightly. Not tough enough! I tested a piece of shaft I'd cut off and discovered it was about as rigid as wet pasta. Very mild steel! The only reasonable solution I could come up with is show above. I drilled a 3mm hole in 3/16 steel shaft material and slipped it over the 3mm motor shaft. It's held in place with Loctite 660. For added rigidity I also made new end plates for the Silver Spark motors from 2024 aluminum. Of course I also had to drill out the 3mm motor mount holes to .25" and also all the nylon adapters I'd super glued to the paint roller wheels to .1865 for light press fit on the .1875 shaft. Bending problem solved.

Does it work?

Seems to. It does the pushy bot thing very very well. Excellent pushing power and agility . Due to its symmetry it runs inverted as well as upright. We'll find out how it works in actual combat Jan 31 2015 at Robot Battles 53 in Chattanooga TN. Will it win? Will it survive? Will everyone die of pushy bot boredom? Stay tuned ...

Jan. 31 2015

Death by Twinkies won the 1# championship at Robot Battles 53 at Chattacon in Chattanooga TN. One flaw was discovered. Drum bot Grinder removed two wheels during the rumble. I need to work out a better way to attach them. Other than that it performed flawlessly. It uses very little battery power. I recharged exactly zero times. The 7.4 volt battery measured 7.9 volts after the event! I figure it has at least 80% left. Best of all nobody died of boredom because each of the one-on-one matches lasted less than 30 seconds.

Feb. 5 2015

This is the new wheel attachment system. I milled a flat (.015 deep) on the motor shaft and made an aluminum insert for the paint roller that is a tight pressfit (also knurled) with a #2-56 set screw to hold it on the motor shaft. This should be pretty solid. I suppose the next weakest failure point is either the motor shaft to output gear connection or plastic insert in the foam.

I also had to redesign the 3D printed motor mounts for countersunk screws so the set screw would not hit them.

May 9 2015

Freeside Atlanta Robot Street Fight

This happened.

Algos ( by Michael Jeffries) has a bad ass 10,000 rpm "drumlet" that took big chunks out of the 1095 steel scoops. Video below.

May 21 2015 update

Since 1095 spring tempered steel shattered when hit by Algos weapon I decided to do a little research to see if any other material would hold up better. To that end I built a test rig to simulate vertical spinners. It's a 45 degree angle slide of death with a die grinder powered spinner at the bottom. The rope tether keeps the sled from hitting the ceiling.

I attach the material under test to the little sled, rev the die grinder to 10,000 RPM and release the sled. BANG! Stuff gets bent or broken. Well, most stuff. The exception was polycarbonate, aka Lexan. As long as it's allowed to flex it usually only shows minor scrapes and small depressions. If hit on edge it will crack like most everything else. Things that always bent or cracked include S7 tool steel, aluminum, titanium and UHMW.

Polycarbonate inserted in test sled.

The rebuild

So, counter intuitive as it may seem, I rebuilt Twinkies in Lexan. I used .093" material for the body and .125" for the scoops. The bot weighs the same as before.

Cold bending Lexan is a little tricky. The bend line will be brittle unless the piece is annealed in an oven at 250F after bending. But, this causes sagging and warping. I had to clamp the parts between rigid metal forms to hold the shape while in the oven. The forms were simply pieces of aluminum bent to match the bot parts.

We will find out how well it works next September at Dragon Con Robot Battles.

The new all plastic version!

Twinkies was defeated in the first single elimination round at Dragon Con Robot Battles by another wedge so it's plastic body was not tested by and high KE weapons. I still don't know how well this will work.

Dec 5 2015

Robot Battles 57 at the Joystick Gamebar in Atlanta.

Twinkies got a lot a air time at this event. It made it all the way to the finals where it lost to Algos by Michael Jeffries. (Again!) It won the Rumble with only 2 of the 4 motors working and one scoop missing. I had to replace all 4 twinkie wheels and 3 scoops during this event. I did not have a spare body panel to replace the one that had it's scoop attachment points ripped off. That was a major handicap because Twinkies was not invertable running with a scoop one one end only. Well, it was invertable but was scoopless on the front end.

Here's where the scoop was lost.

By this time only two motors were working and I had only one scoop.

The 1# Rumble

Play list of all fights at Robot Battles 57

Here's Twinkies after the event! Note the paint failure. I've been told I need to use polycarbonate paint. A few design changes are in order too.

Hit Counter = 14303

Previous page: Electric Whirligig

Next page: Dead Air, a 16oz combat bot