Flip-O-Matic

March 28th 2008

What is it? A new combat robot weapon! As the name implies, it's a flipper that automatically operates when it contacts the opponent. I don't have to push a button at exactly the right time - the opponent fires it himself at the correct instant for optimum force. And best of all, the trigger is simple and completely mechanical.

This experimental unit is designed for 30 pound bots. It should exert about 500 pounds of force for 30 milliseconds. It works out to about 8 horse power during that short time! In theory it should launch the opponent about 5 feet. Unfortunately the real world will insert its losses and other mysterious influences and conspire to reduce that considerably.

CNC mill cutting pockets in gear box

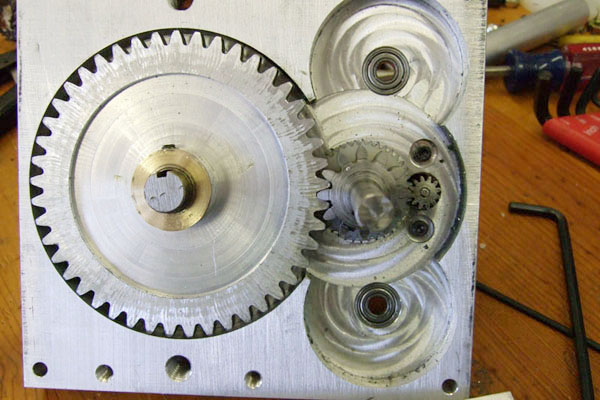

The power unit is a custom made gear box CNC'd from two pieces of 3/4 inch 6061 T6 aluminum. Inside are two gears that reduce the 30,000 RPM motor speed to 2400 RPM on the output shaft. On the intermediate shaft is a 3.5 inch flywheel that turns at 9000 RPM and stores about 400 Joules of energy.

CNC cutting teeth on gear

Yes, I make custom gears.

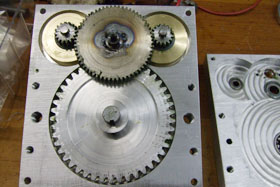

Dog Clutch Assy. (Disengaged)

On the 2400 RPM output shaft is a 12 tooth gear that drives a 45 tooth gear on the dog clutch assembly. The dog clutch spins at 640 rpm. Resessed in the 45 tooth gear is an disk that turns on the same shaft as the gear but is not coupled to the gear. There's a cutout in the disk with a carefully shaped "dog" that will engage one of the two inner protrusions on the 45 tooth gear. The dog is held in a retracted position with a small spring. If the dog is forced outward it will engage the inner protrusion of the 45 tooth gear and cause the inner disk to rotate with the gear. A connecting rod couples the dog to the flipper arm. When the opponent bot presses on the flipper the dog is forced outward engaging the gear. The inner disk will rotate about 120 degrees with the gear until the external forces on the dog cause it to retract, at which point it automatically disengages.

Dog Clutch Engaged

Dual Flywheel version

Originally I planned on using two flywheels enclosed in the gear box. They would spin at 33,000 RPM. Unfortunately there was way too much friction and the motor pulled 20 amps straining to keep them moving. Without any flywheels the motor only needed 5 amps. I suspect the losses were in the bearings.

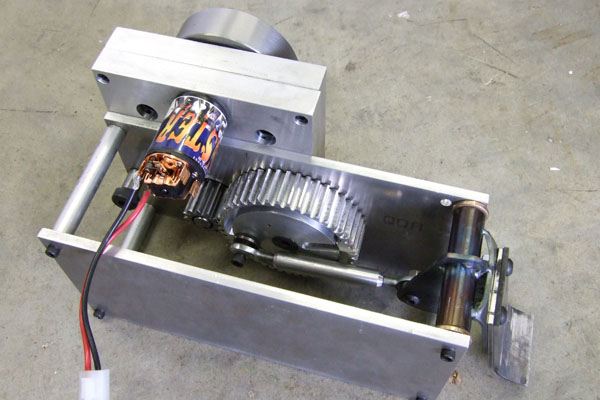

New 9000 RPM external flywheel and gears

I modified the design by placing a much larger flywheel on the 9000 RPM shaft externally. The new flywheel stores the same energy as the pair of small ones. The new configuration got rid of 4 bearings and 3 gears. The friction went way down. The motor only pulls 5 amps after getting the new flywheel up to speed.

Simplified gearbox drives external flywheel on back

Testing

I used a wooden test platform on wheels filled with bricks to bring the weight up to nearly 30 pounds. By rolling it into the flipper and recording the event on video I was able to test the effectiveness of several flipper designs. The flipper is made from 1/8 thick tool steel heat treated to spring temper. The curved scoop shaped flipper worked the best.

During one test the bolt holding the dog clutch together came loose resulting in some violence and destruction. The clutch rotates counter-clockwise which torques the bolt/axel in the "un-screw" direction. I need to re-design it so it spins the other way.

FYI, to keep the Flip-O-Matic from scooting across the room in the opposite direction it was backed up by a section of railroad rail weighing about 75 pounds.

Since a video is worth about a million words I'll let you see the results for yourself.

Testing video

This weapon was refined and installed in a 30# robot named Overthruster. Details here. It won at Dragon*Con Robot Battles 2008.

Hit Counter = 38661

Previous page: Uphill Roller

Next page: Spinning Compass