Noodles

August 24 2016

(Updated June 14, 2018)

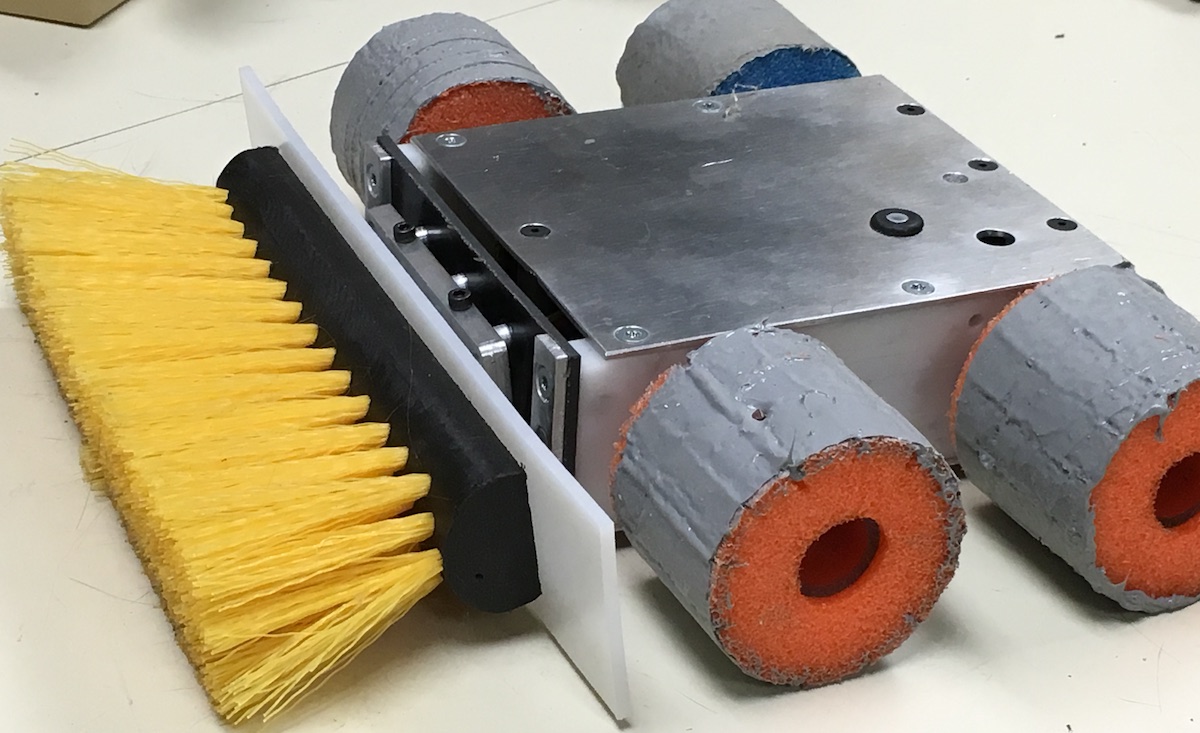

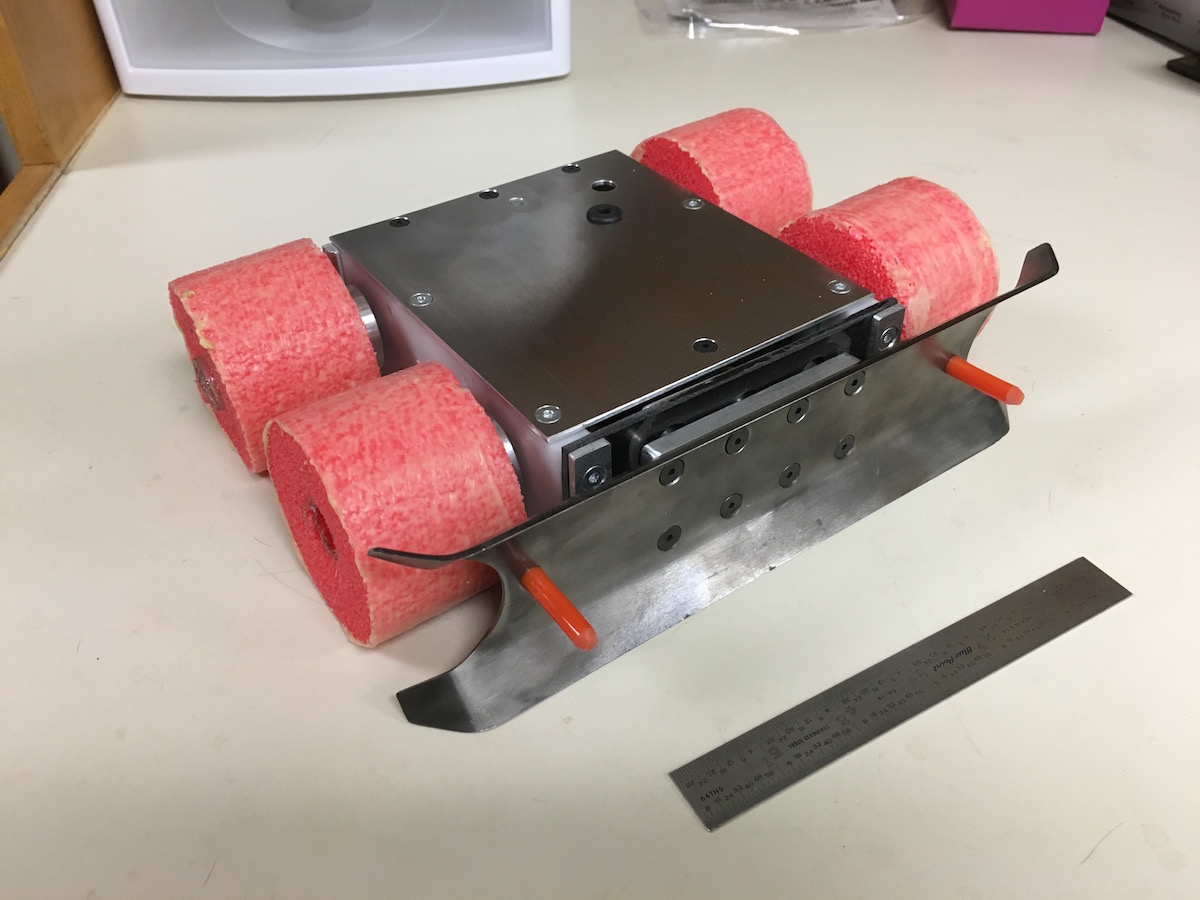

Exciting news everyone! I've made exactly what the robot combat community needs - yet another pushy bot. Meet Noodles, a 3# combat bot powered by brushless outrunners with a big hardened S7 steel dozer blade.

What you see above is the 3rd iteration of the "design". Almost everything was rebuilt at least 3 times before I was satisfied with the result. It started out as a 2 wheel pushy bot with a 45 degree flat wedge. It's main problem was lack of any reliable way to self-right. I hoped it would have enough power and traction to simply flip itself back over by doing a wheelie but the steel wedge made it too nose heavy for that to ever work. Even running it into the wall failed most of the time.

Next I made a bulldozer style wedge that would work inverted. That solved the self-righting issue by just running it upside down but the heavy wedge took weight and traction away from the wheels preventing it from being very effective at actually pushing anything. However, it was about 8 oz under weight so I figured maybe I could go 4WD without exceeding 3#. I was right.

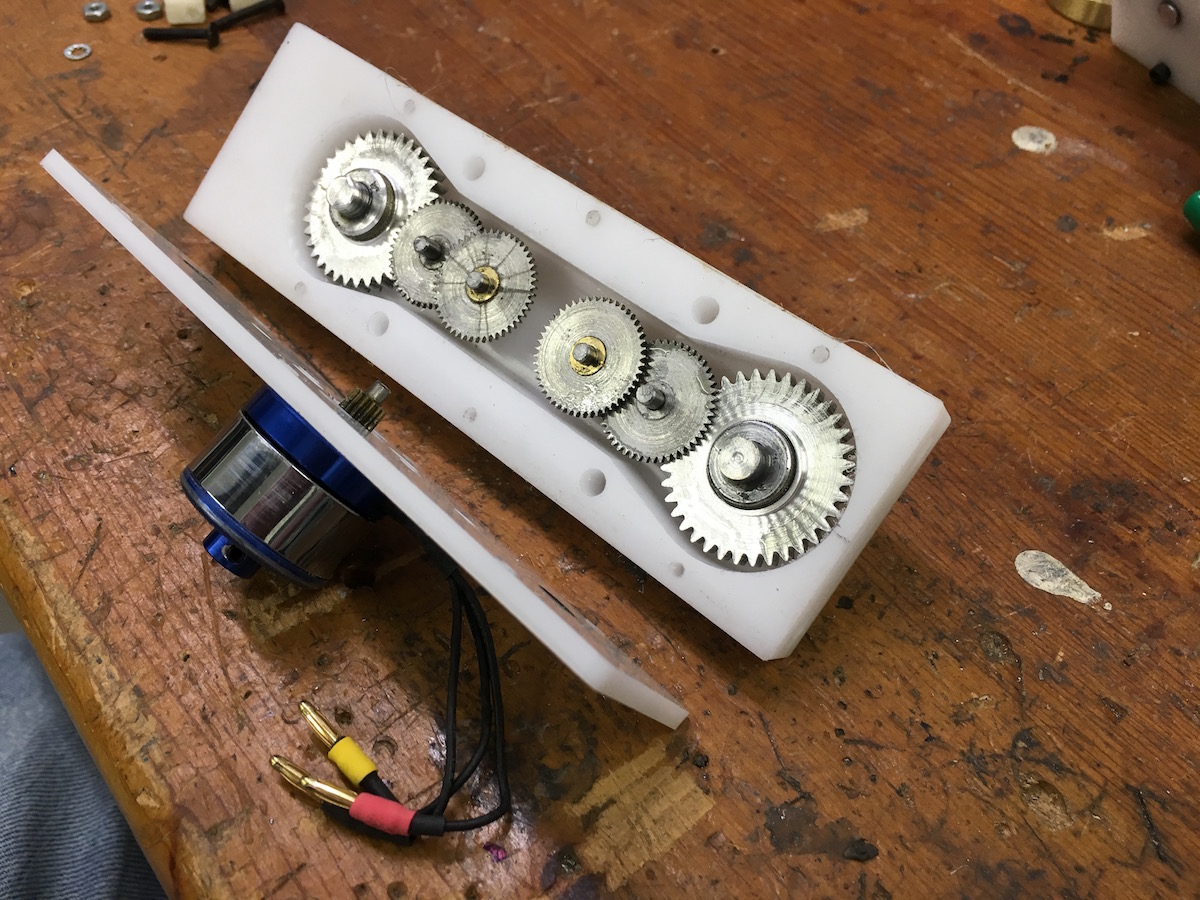

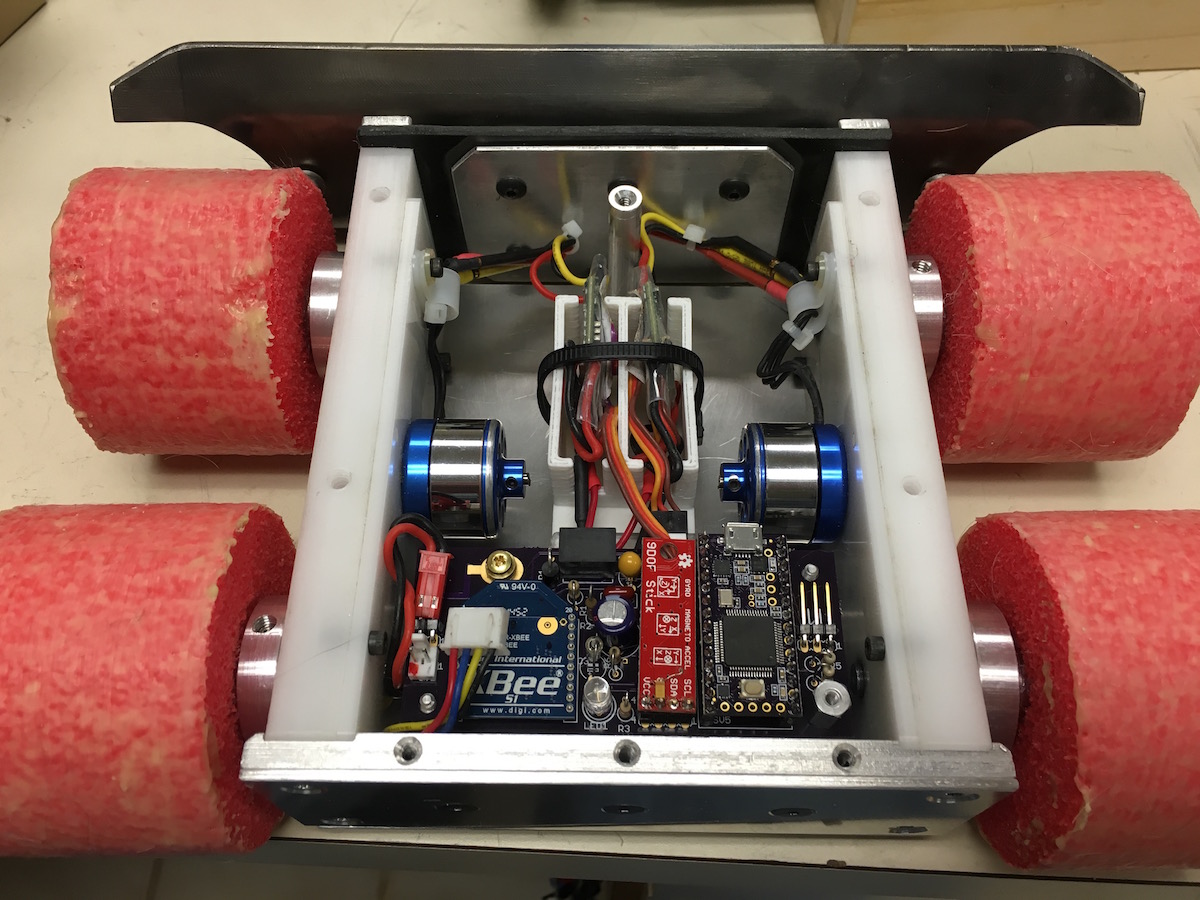

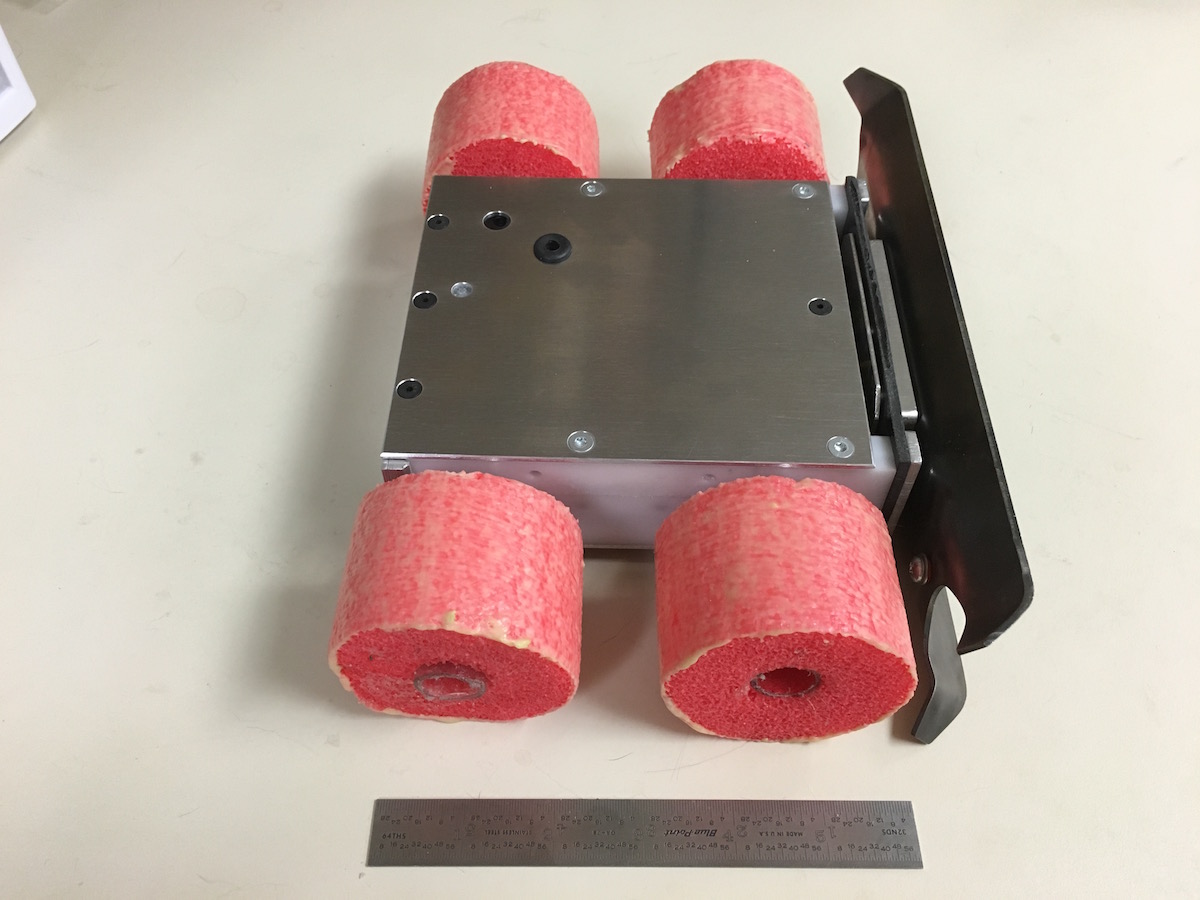

The final configuration is 4WD with two brushless 1600 KV outrunners powering the wheels through a pair of custom 27:1 gearboxes embedded in the side panels (below).

These are physically the same motors and gears I used in Electric Whirligig which has been completely disassembled and no longer exists. (it sucked) The side panels/gearboxes are machined from 1/2 inch thick Delrin. The ratio is 27:1 With 2.6 inch tires top speed is about 7fps.

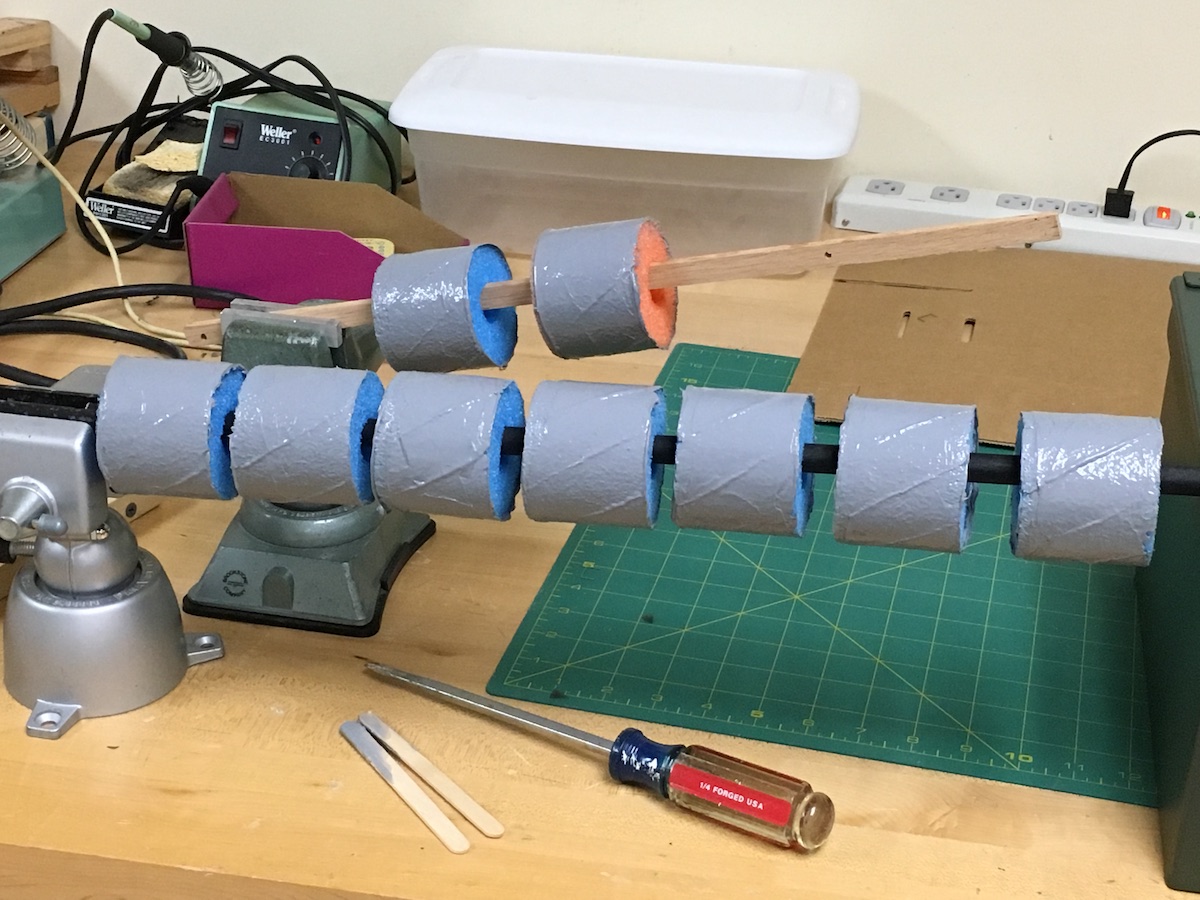

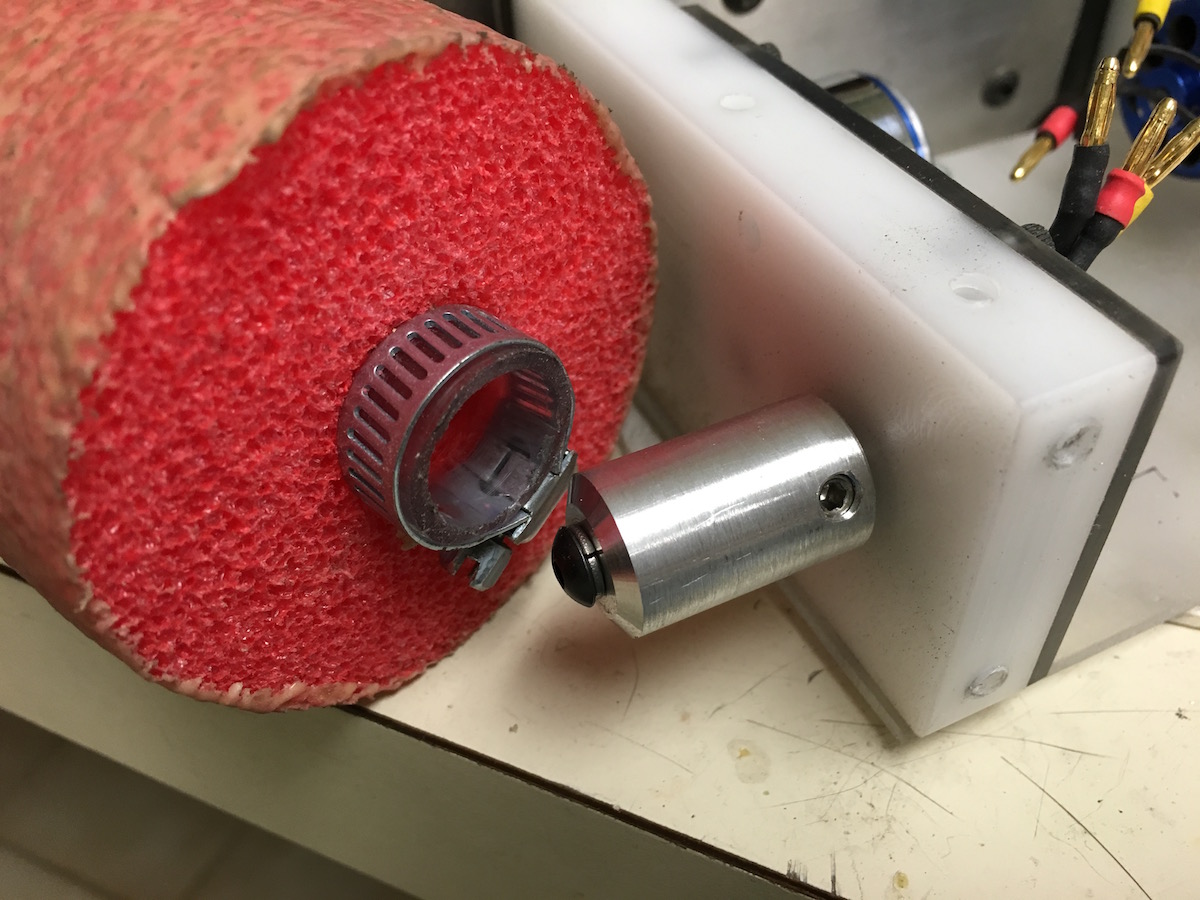

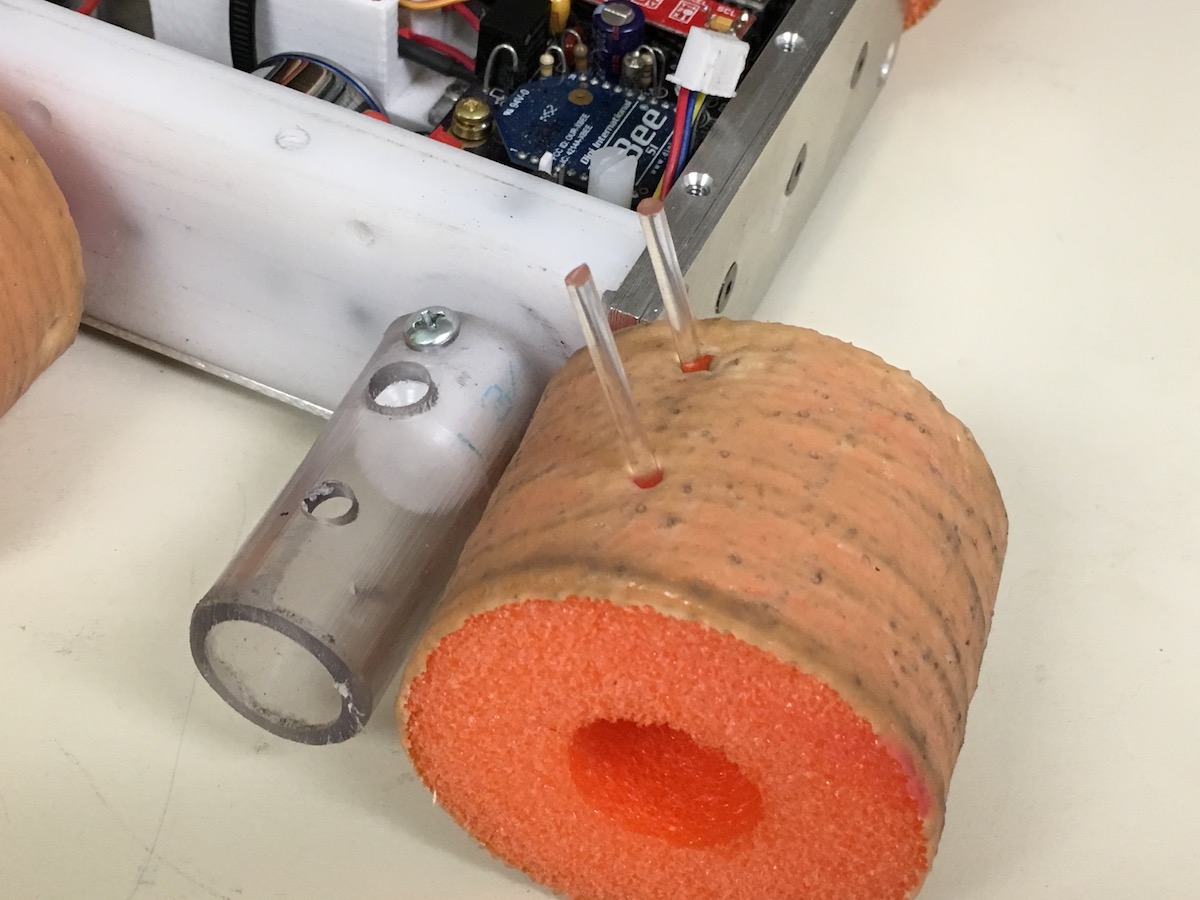

The wheels are made of 2 inch pool noodle segments. This is how they are attached. 3/4 OD vinyl tubing is pushed through the pool noodle segment and glued with Goop. The 5/8 ID slips over the drive axle and is clamped.

For better traction the wheels are first coated with rubber cement, then 5 minutes later the first of 3 coats of brush-on latex is applied.

These things can take a lot of damage and still function. Also they don't transfer much energy to the axle when hit.

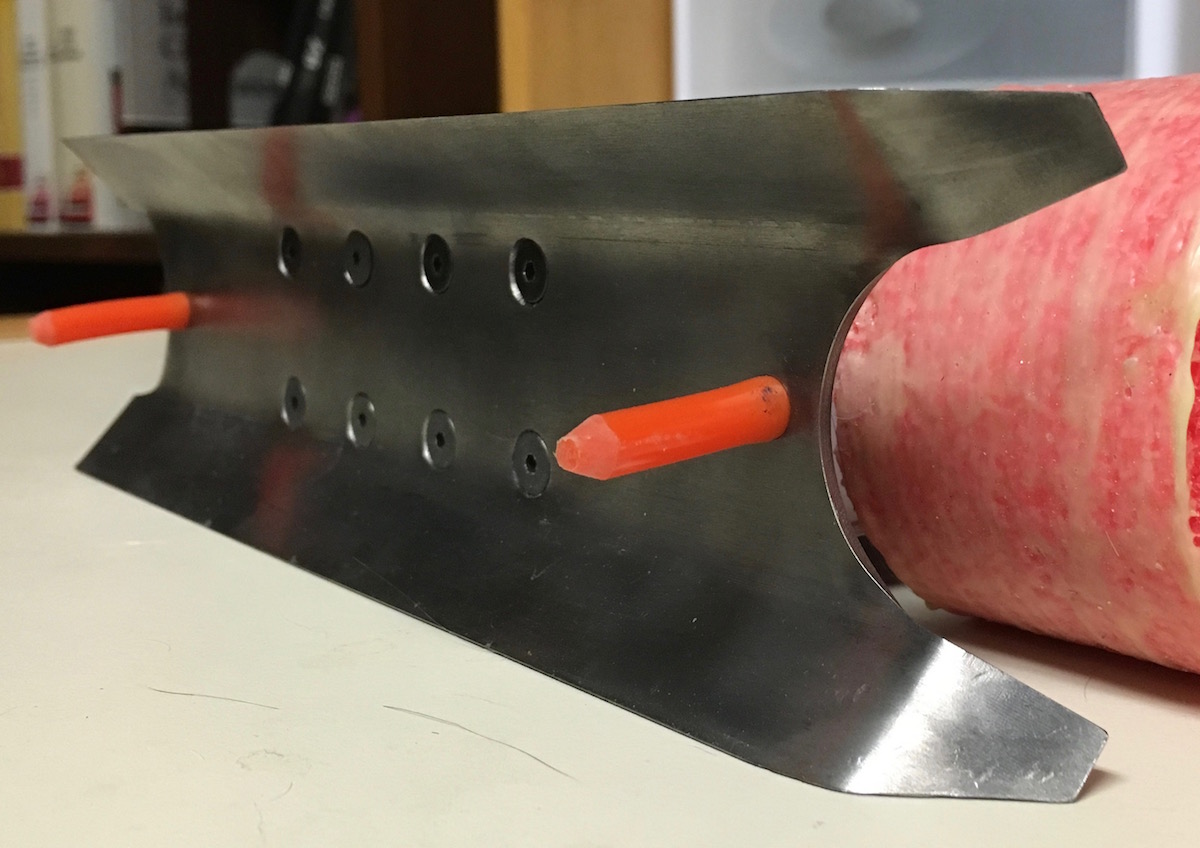

Above is the process of making .125" S7 tool steel into .070" S7 tool steel for the dozer blade. The round bar clamped down on it prevents it from bowing up in the middle. Half was milled down then the bar moved and the other half milled. After thinning it was CNC cut to shape then bent with metal brake and a hammer. Once bent to the desired shape I mounted it in the mill and trimmed both top and bottom edges to be sure they would be straight and make perfect contact with the floor.

Are we done yet? No! S7 comes annealed and must be hardened to resist being mangled by Jamison Go. Basically, heat to 1725F, air cool, then bake at 400F for a couple hours. Wire brush to remove scale. End result below. The orange pegs are urethane and prevent it from getting stuck standing nose down on the dozer blade.

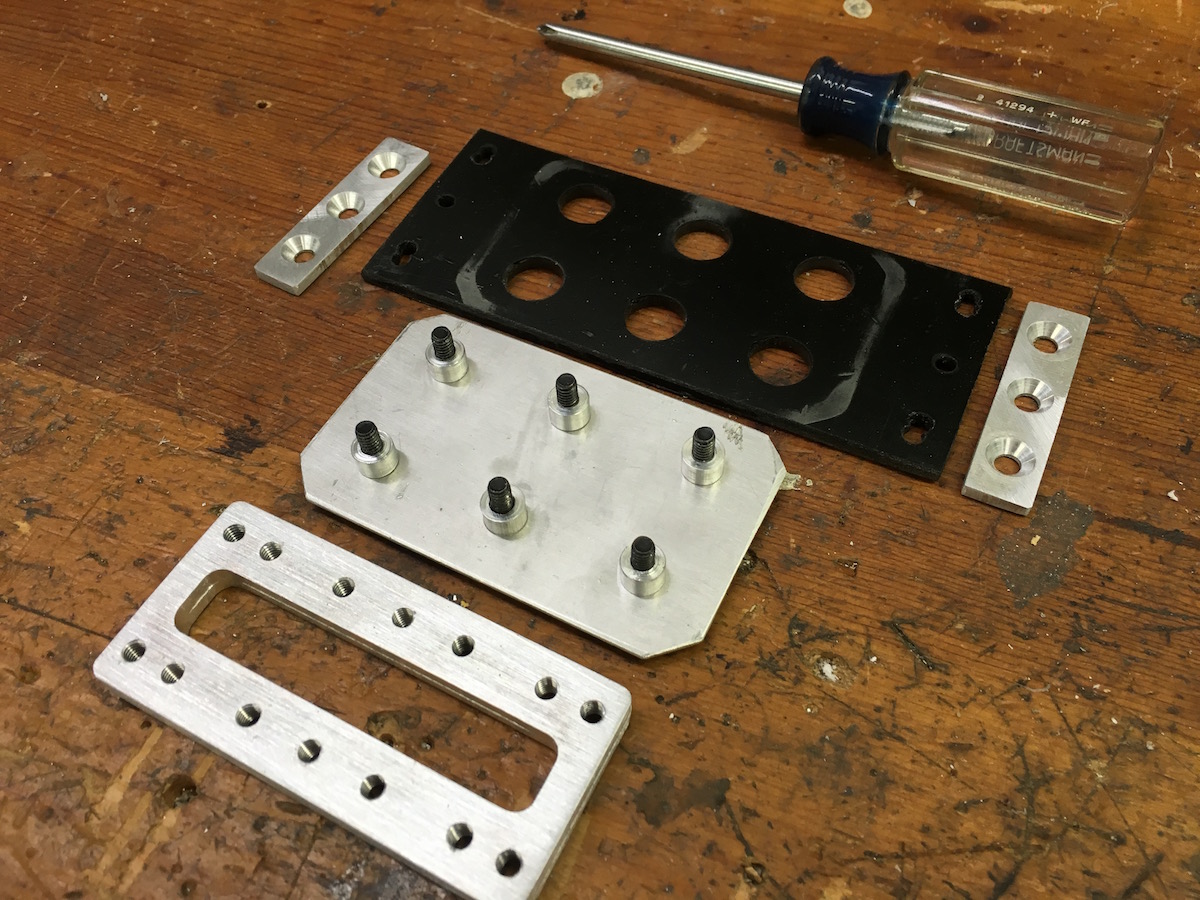

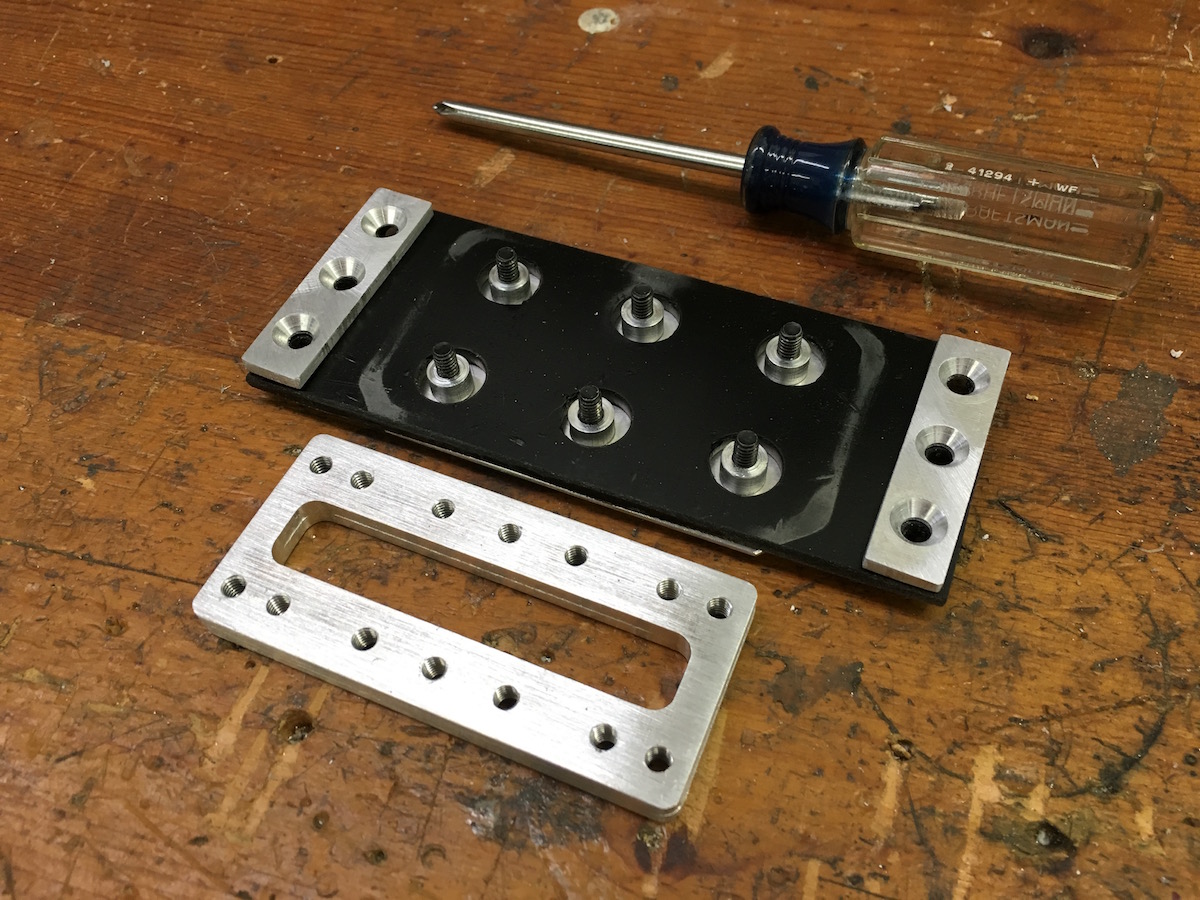

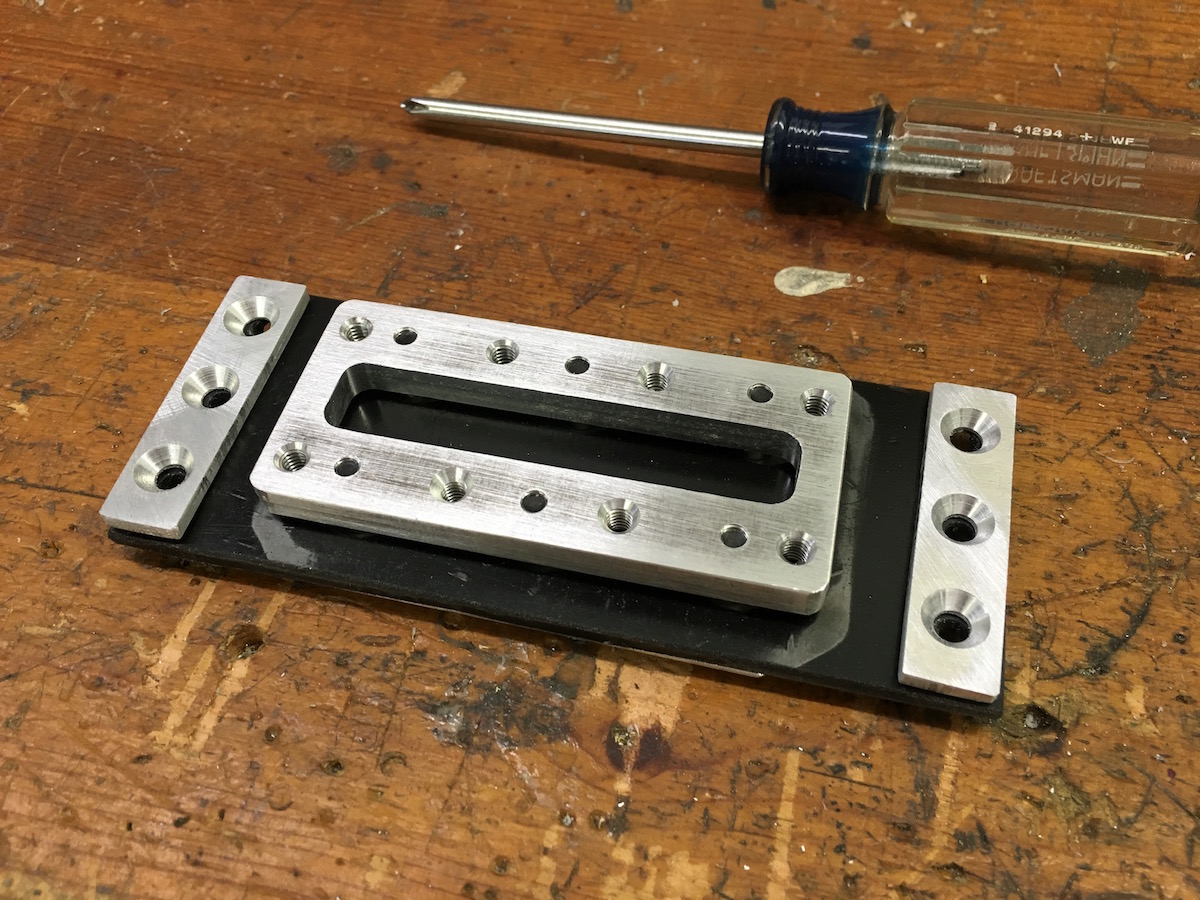

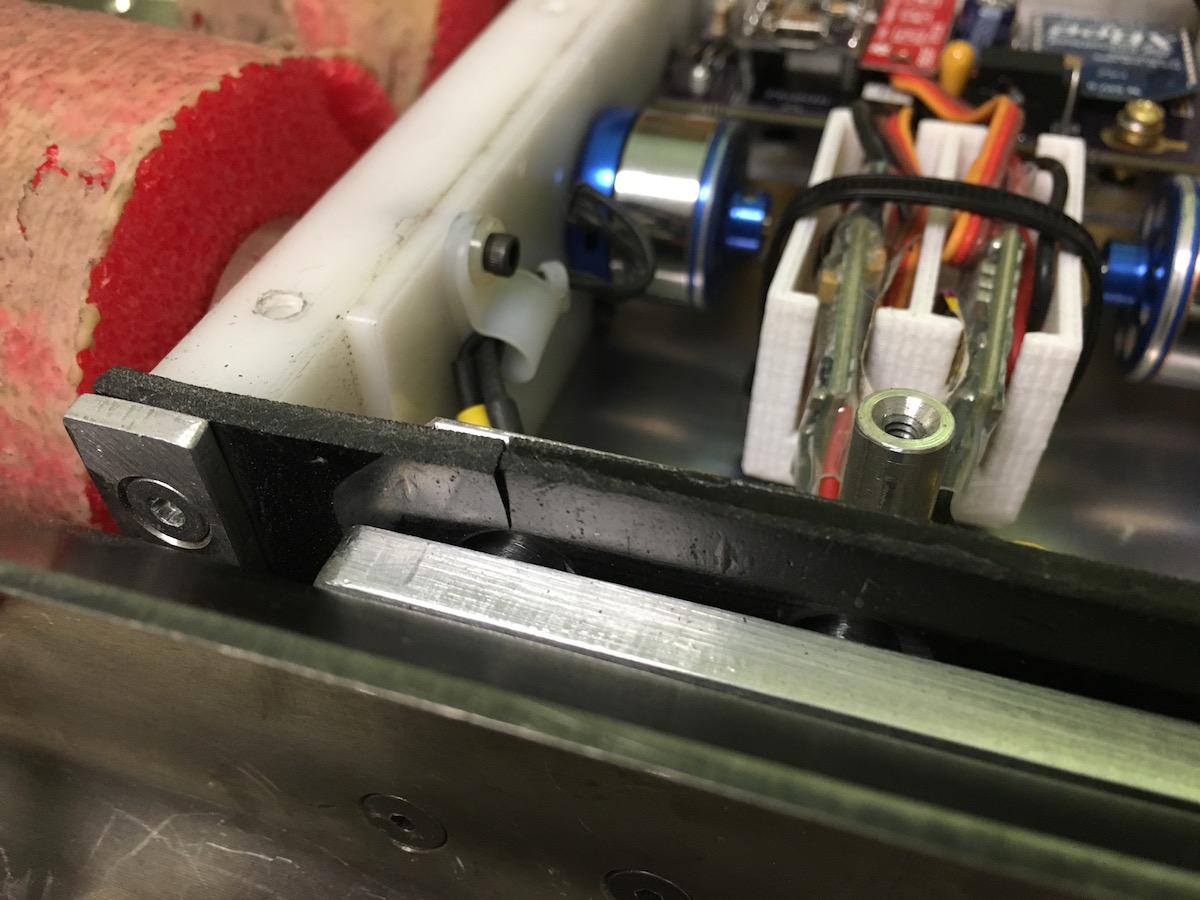

Ok, the blade looks pretty bad ass but how do I keep it from being ripped off the bot by an even more bad ass spinner? Hopefully the answer is in the photos below.

The dozer blade floats on six 5/16" spacers in 1/2" holes in 1/8" thick urethane rubber sheet. This gives it 3/16" freedom of movement so it can lay flat on the floor. The rubber (hopefully) will absorb shock. The rubber assembly is screwed to the body with six #10 3/4" long self tapping screws.

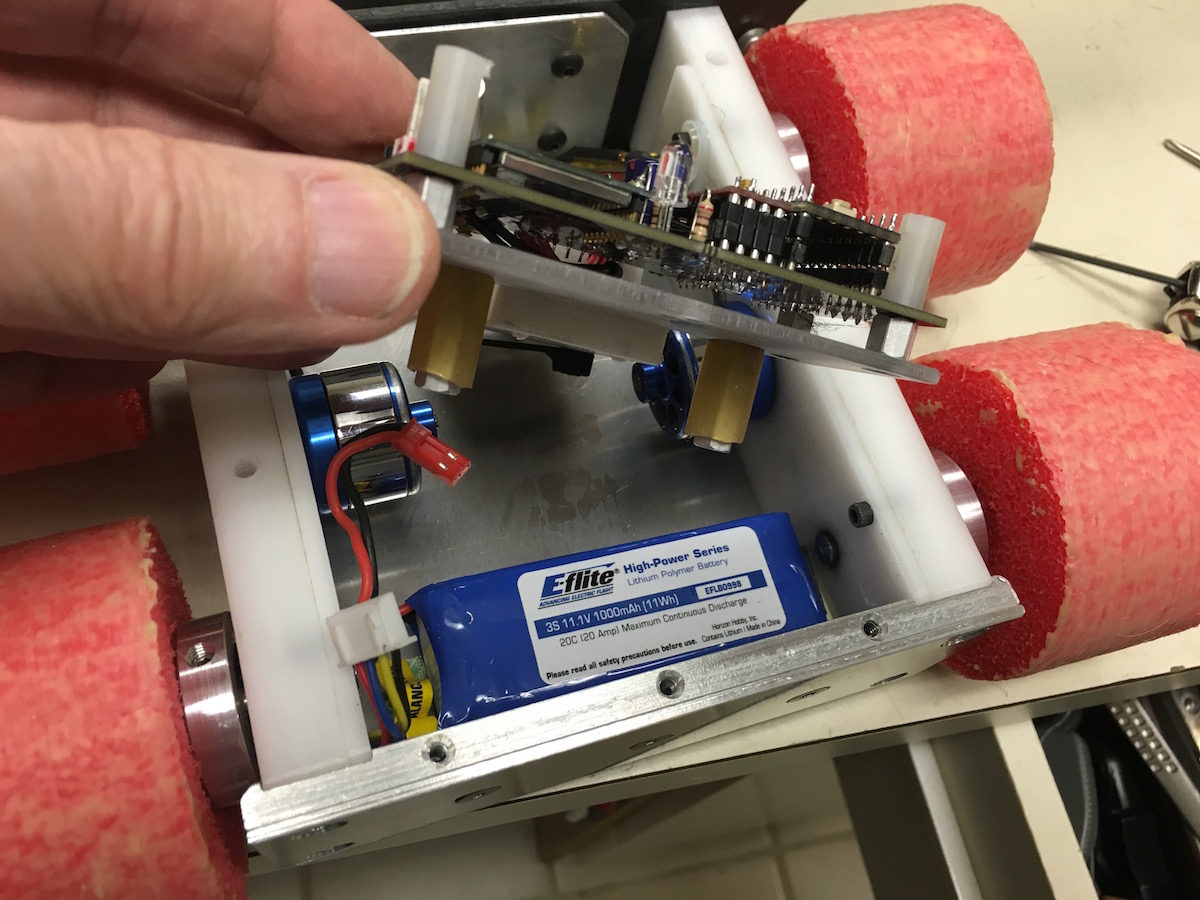

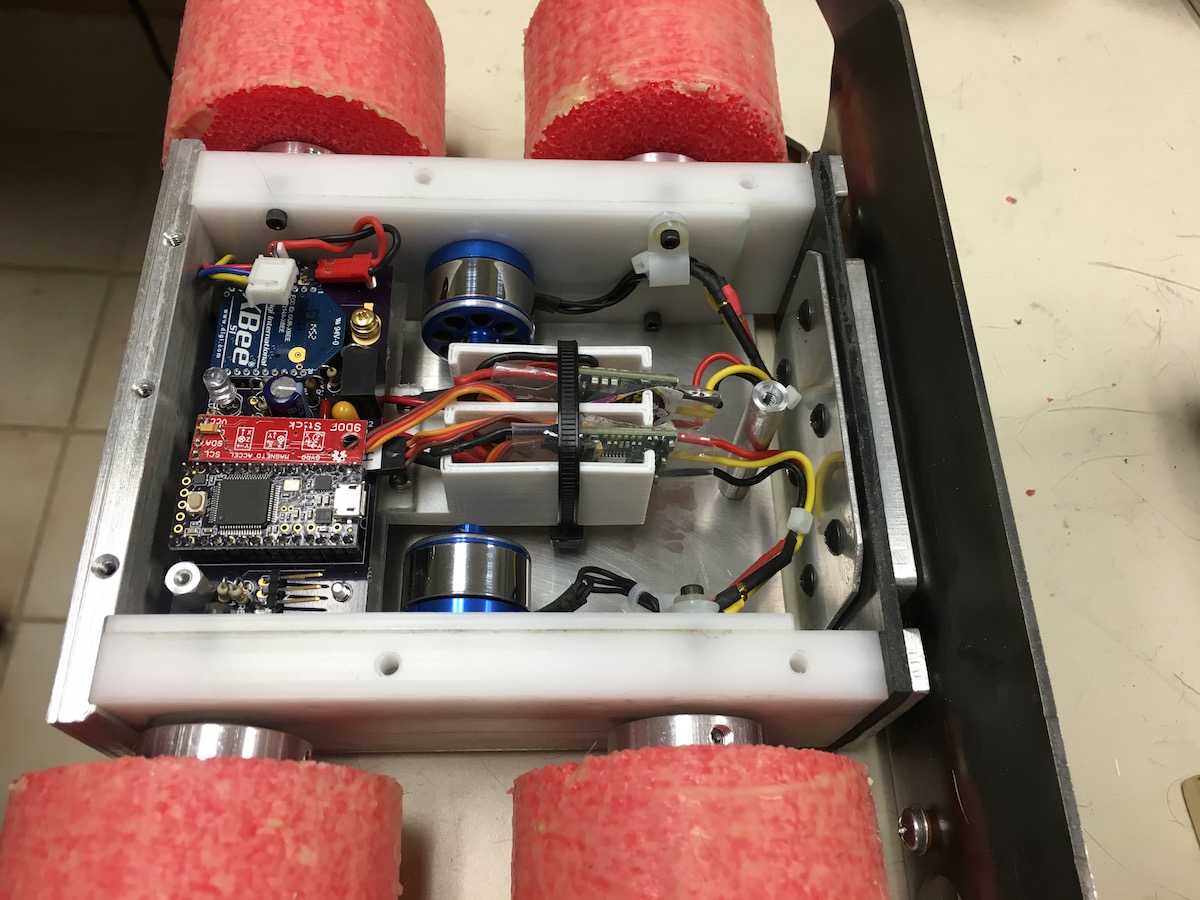

Custom PC board with XBee radio, SparkFun 9DOF gyro/accelerometer/compass, Teensy 3.2 controller. The power switch is the gold pad with brass screw on the left. Turning screw shorts top to bottom traces on PCB and turns on power. A pair of 12 amp Afro brushless ESCs with SimonK firmware from Hobby King are in 3D printed pockets between the motors.

The accelerometer is used to sense when the bot is inverted so the controls can be automatically reversed. The gyro signal is used as heavy negative feedback to the steering. Without it the bot is impossible to drive without severe steering overshoot.

The battery is stashed below the electronics.

Finished. The top and bottom panels are .080 2024 aluminum. Access to the power switch screw is via the black rubber gromment.

Here's a video of Noodles pushing stuff around and showing off.

We will be at DragonCon Robot Battles on Sept 4 2016.

-------------------

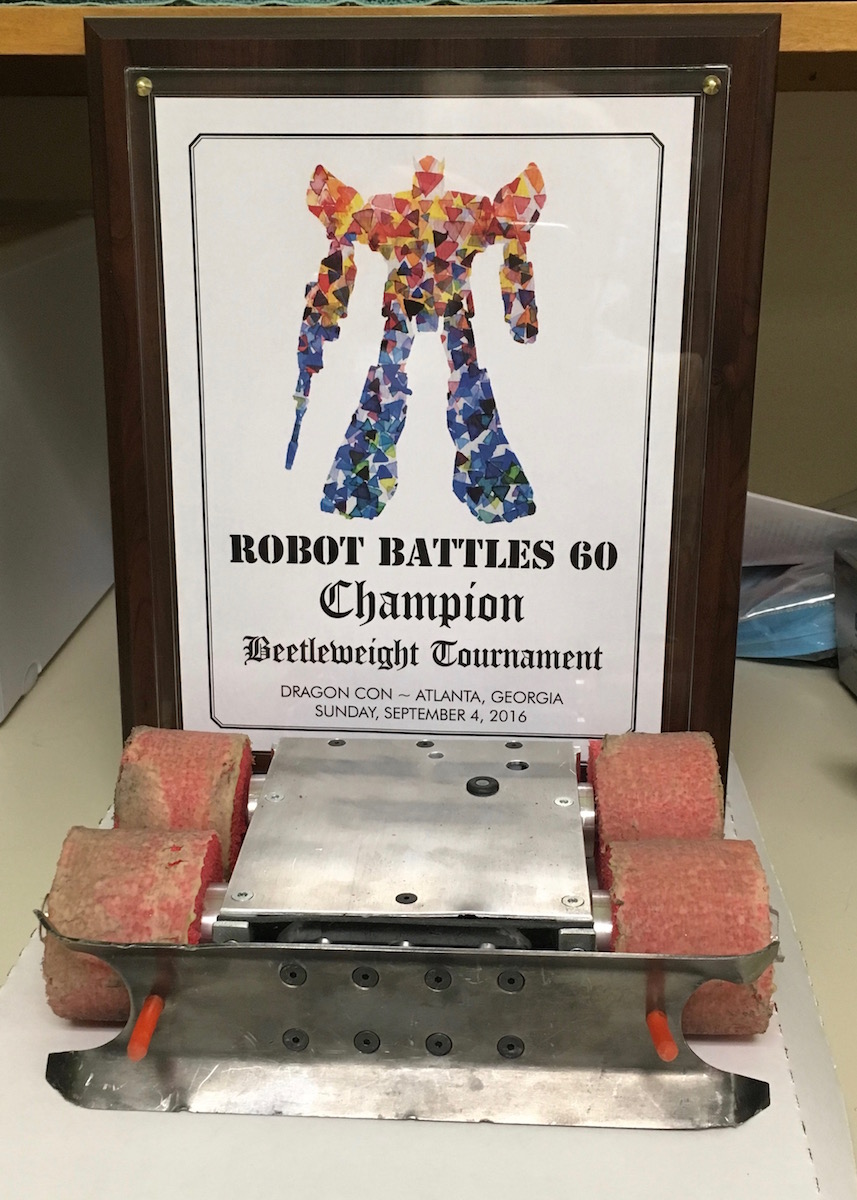

Sept. 4, 2016

Robot Battles 60

Noodles fought Too Big To Flail, Mobile Chernobyl, Gor Gor and won all by judges decision. In the final he had to fight an extremely powerful egg beater spinner, Black Adder. Noodles took hit after hit and kept on running. Eventually Black Adder ripped off one of Noodles latex tire treads which got stuck in his weapon an stopped it cold. The rest was a pushing match with Noodles doing most of the pushing. Unfortunately I never quite got him to the pit. It went to the judges who rendered a split decision for Noodles! It was close. They took a very long time to decide.

The dozer blade now has several small dings and is a little warped in a couple places. Damage photos below.

All the beetle weight fight videos are here on the Robot Battles YouTube channel.

Aug 25, 2017 Update

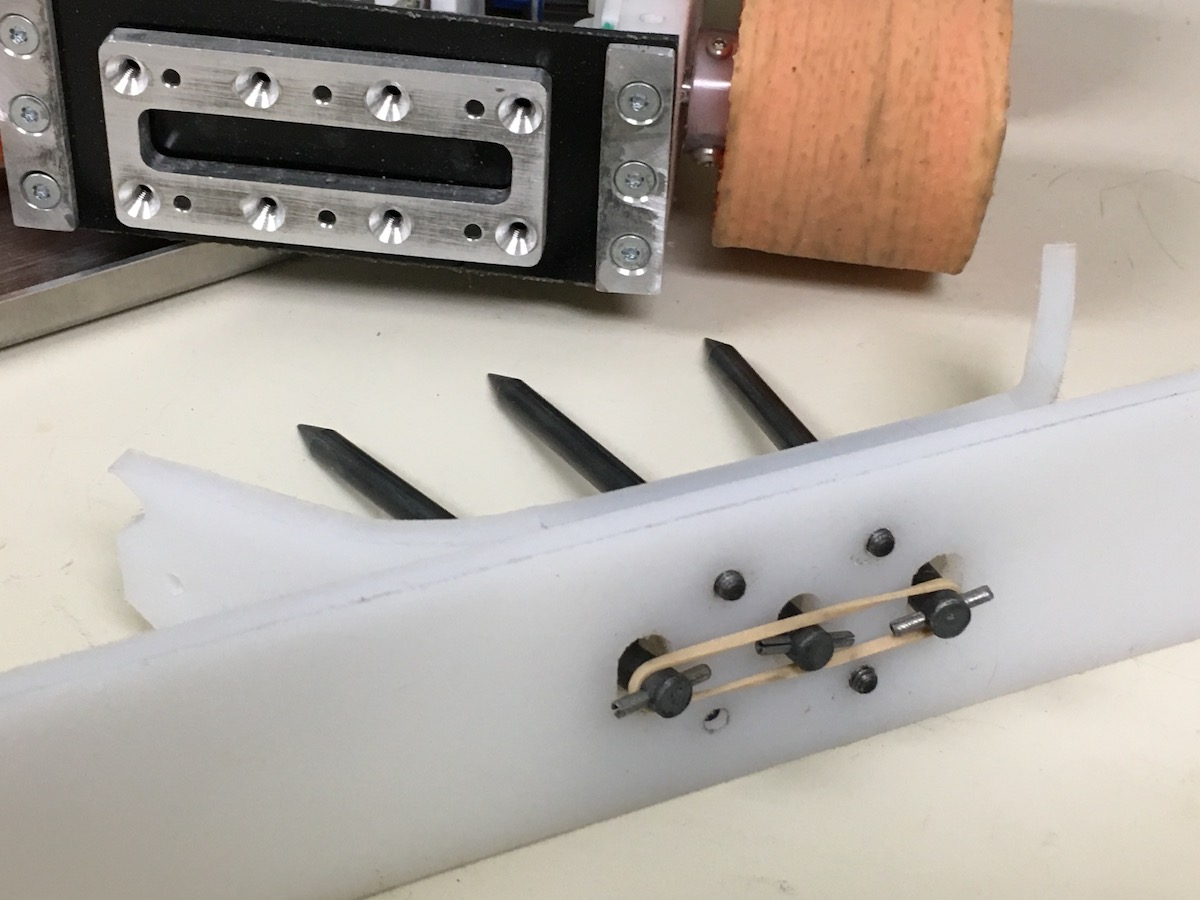

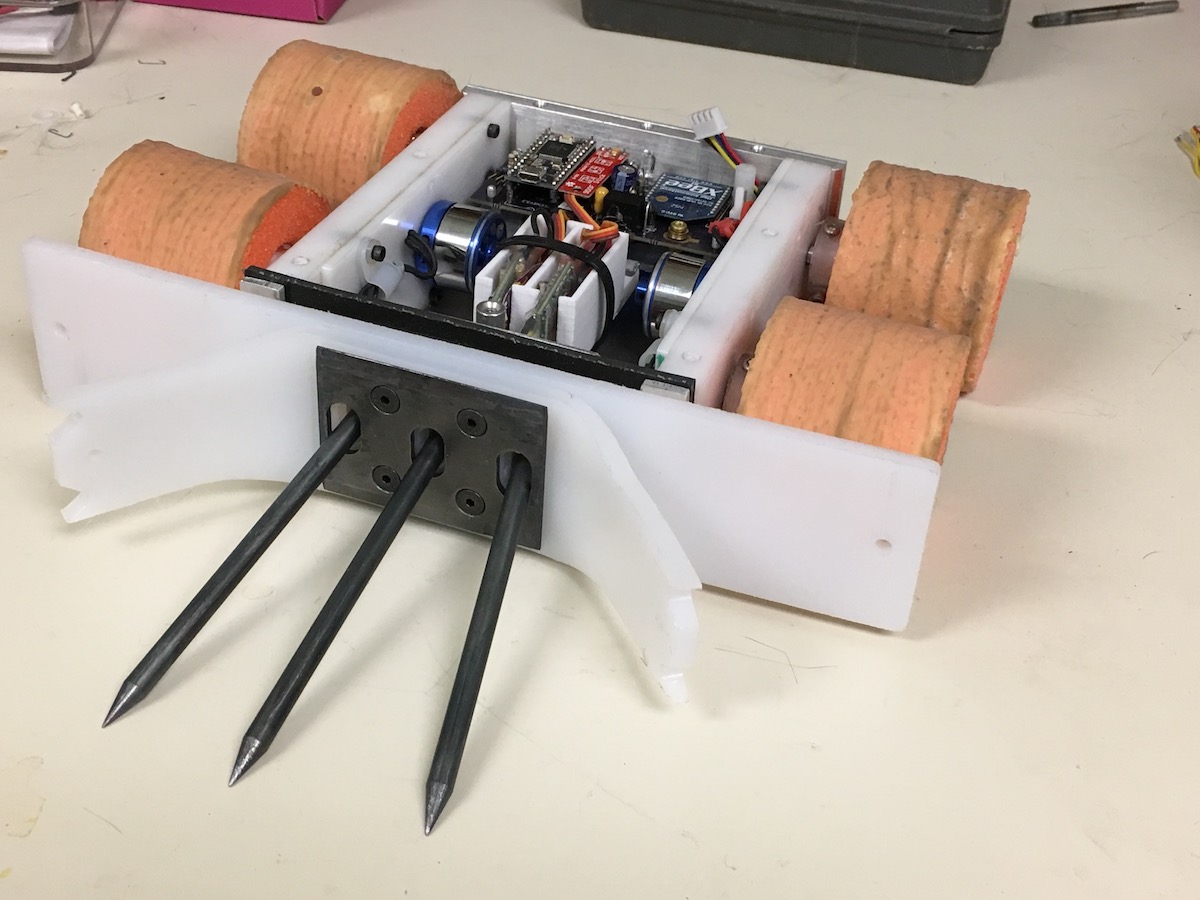

I recently made a completely new front end for Noodles. Gone is the S7 plow and in its place are 3 pointy probes ahead of a couple pieces of 3/16 UHMW. The 3 probes are S7 hardened tool steel. I bent the UHMW by heating in an oven to 330F then forced it into a wood form until cool.

Spring pins keep the rods from rotating and falling out yet allow up/down movement so it can run inverted.

A rubber band keeps the outer two rods spread apart. The rectangular slot in the mounting plate and the spring pins keep the rods from rotating.

Final assembly.

I also changed the wheel attachments . Pool noodle segments are held on the vinyl tube axle with polycarbonate rods pushed through holes.

Next event is Dragon Con Robot Battles Sep. 3, 2017 when physics, Murphy's law and general randomness will judge the worthiness of these changes.

Judgement is passed:

The broken tip and bent rod shown above are unwanted modifications made by a powerful horizontal spinner "Margin of Safery" at Robot Battles 64 at DragonCon. S7 tool steel is not strong enough. Crap.

So, only one thing to do. Counter insanely powerful brushless motor weapon systems with a motorless brush weapon system. LOL! No, seriously.

Update May 23 2018

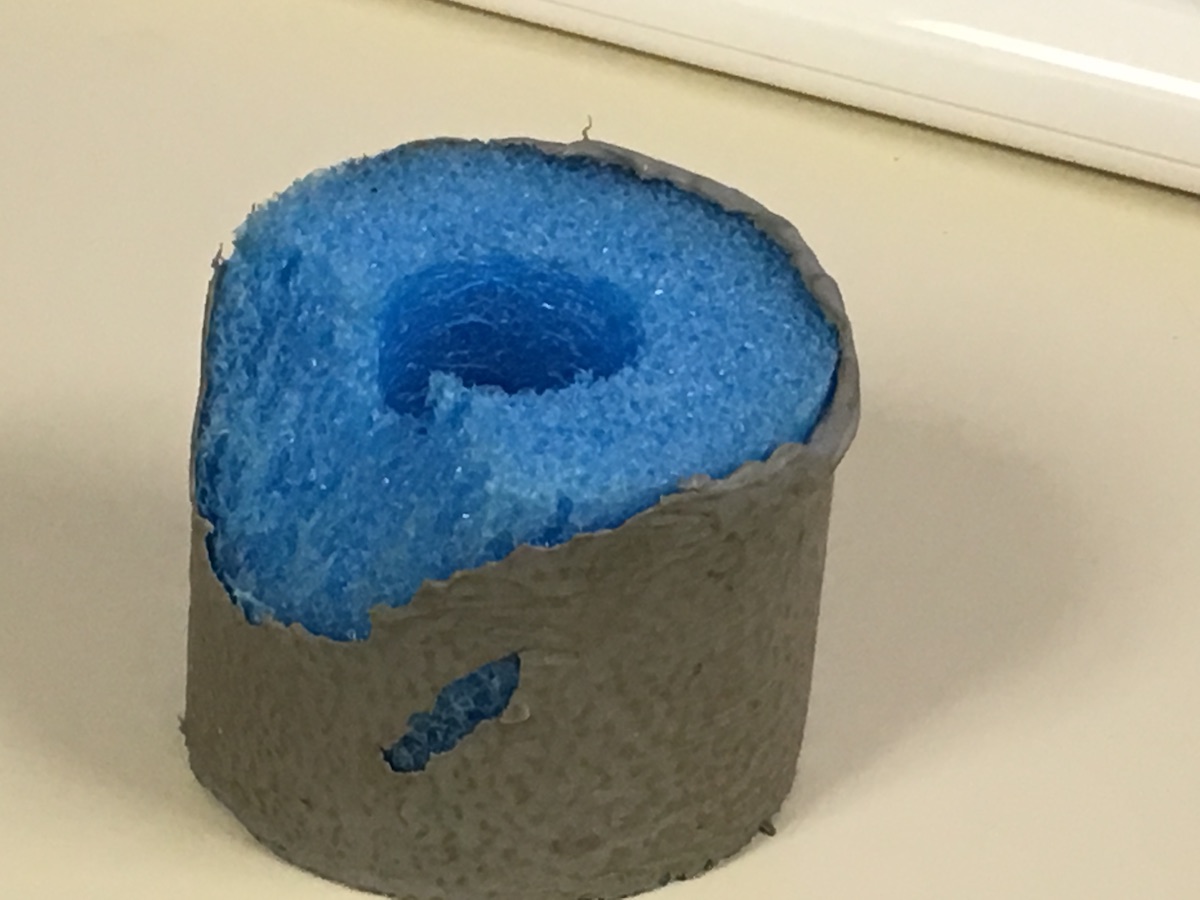

To stop the complaints from jammed up spinner owners I've changed the pool noodle coating. This year I'm coating the noodles with Liquid Nails Fuze*It. This stuff has pretty good traction but doesn't have the elasticity of latex so it cuts cleanly instead of coming off the wheel in one piece.

It dries pretty quick and is easy to apply with a flat stick while the noodle is slowly rotated with a small gear motor. Here are some finished wheels.

Here's a noodle wheel after being hit with a spinning weapon. Note the clean cut. Can you deal with this spinner guys?

Noodles will be at Robot Battles 65 - MomoCon May 26, 2018

...

Well, we're back from MomoCon and down 12 noodle tires and part of a brush. Two bad-ass vertical spinners ( Properly Sloppy and Nautiloid) made sure we didn't win. Thanks to the new spinner friendly tire coating they successfully chewed up all the tires before I could force them to the push-out. Noodles can't do much without tires <sad face> But the brush worked fairly well. The main problem was with the vertical spinner forcing the brush upward and then chewing up the bots underside instead of just launching it into the air like when a wedge gets hit. I'll know more after Mikes videos get posted. Not sure if I'll retire Noodles or try more weird ideas.

Video of Noodles vs Properly Sloppy chewing off all the tires.

We did beat an inverted cooking pot and a pizza cutter though. :)

Hit Counter = 13042

Previous page: Huggy Bear

Next page: T-Boner 2.0