Dewalt Motor #396505

April 9 2008

I bought a couple of DeWalt drill motors part number 396505 from Robot Marketplace to drive a new 30# DragonCon Robot Battles class bot for the 2008 event in September. At $28 they were pretty inexpensive considering the size and power. I'd never used DeWalts before and was clueless about the specs and mounting methods. They assume the customer is going to buy the DeWalt gearboxes and mounting hardware. But, I like to make my own custom transmissions so I just bought the motors alone. The web site doesn't provide any dimensions or power/speed specs. I figured since they were so cheap I could work it all out and if they couldn't be used it's no big loss. Anyway, how hard could it be?

I bought a couple of DeWalt drill motors part number 396505 from Robot Marketplace to drive a new 30# DragonCon Robot Battles class bot for the 2008 event in September. At $28 they were pretty inexpensive considering the size and power. I'd never used DeWalts before and was clueless about the specs and mounting methods. They assume the customer is going to buy the DeWalt gearboxes and mounting hardware. But, I like to make my own custom transmissions so I just bought the motors alone. The web site doesn't provide any dimensions or power/speed specs. I figured since they were so cheap I could work it all out and if they couldn't be used it's no big loss. Anyway, how hard could it be?

First parameter to measure was the Kv or RPMs per volt. They are rated at 14.4 volts. I set my power supply on 10 volts, made a disk half white and half black and pressed in on the pinion gear. I power it up and used an optical tach to measure RPM. The motor has a big plus sign on one terminal. I measured the speed with both forward and reverse polarity. Sadly it seems the motor has advanced timing and runs faster forward than reverse.

Kv forward: 1325 RPM per volt or 19080 rpm at 14.4 volts

Kv reverse: 1235 RPM per volt or 17784 rpm at 14.4 volts

This is not good. If identical transmissions are used on both sides of the bot, the motors need to run in opposite directions. One side will run 7.2% faster and the bot will not track a straight line. However, this can be overcome one way or another.

Kt in inch-ounces can be computed from Kv with this formula:

Kt = 1355/Kv

So, 1355/1325 = 1.02 in-oz torque per amp for this motor.

Next I measured the pinion gear to see what would mate with it. The OD of the 15 tooth gear measured 12.3mm . Assuming metric gears to find the module you divide the OD in millimeters by the number of teeth + 2. So 12.3 / (15+2) = 0.723 . Hey! This is not a standard module for metric gears. Hmm, maybe it's English instead. To find the pitch you divide the number of teeth + 2 by the OD in inches. So, 17/.484 = 35.12 Hey! That's not a standard pitch value either. The closest one is 32. So it seems DeWalt has used gears based on the standards of some extrasolar alien race, or possibly the Chinese. The existing pinions are useless. Now the question is: Can they be removed in my shop without exotic processes ?

I made some inquiries on the Robot Battles email list and learned from Team TestBot and Team Davinci that the pinions can be removed if a custom made puller is used. It was clear from the replies that a lot of force would be required.

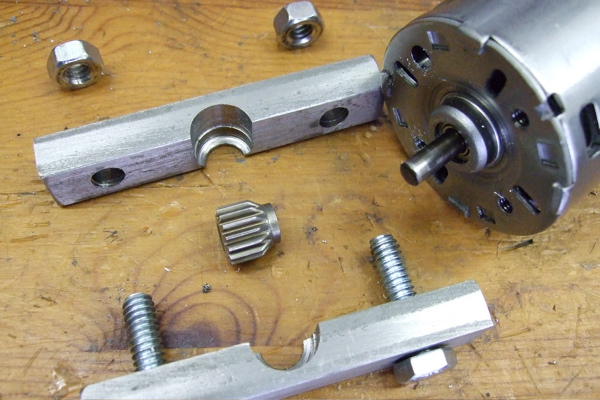

Custom made gear puller & alien technology pinion.

Above is a photo of the pinion removed from the motor and the two piece puller I made from a piece of 1/2 x 3/8 steel bar. I drilled two 1/4 inch holes 2 inches apart to hold the halves together. I bolted the halves together and drilled a 0.339 inch hole (R drill) all the way through and centered between the 2 pieces. I followed that with a 12mm hole almost through so a thin lip remained to catch the pinion gear. If you try this a home kids, be sure to run the drill press at about 500 rpm and clamp the work in a drill press vise clamped to the table.

Using arbor press to remove the pinion gear

With the rig shown above the gear came off without problems. A lot of force was required!

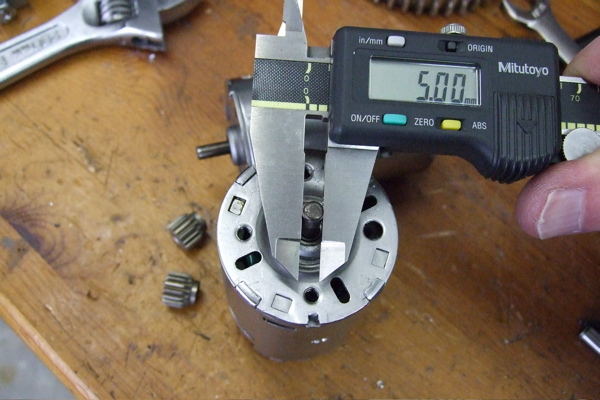

Motor shaft is exactly 5mm

Wow! The motor shaft is not based on alien technology standards. It's 5mm. Now I need to get a standard gear on that shaft.

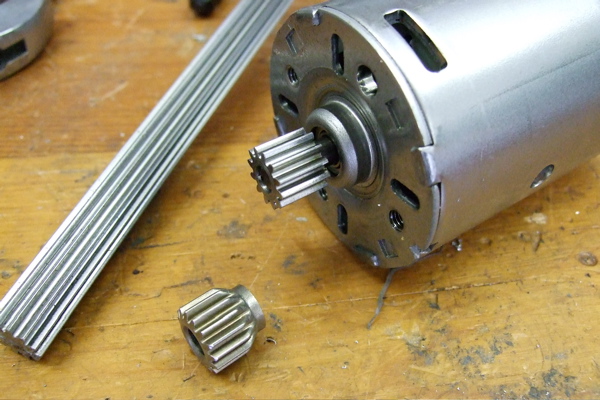

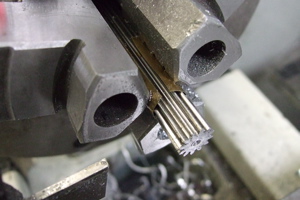

12 tooth 32 pitch pinion gear pressed on 5mm shaft

I started with a piece of 12 tooth, 32 pitch gear rod from McMaster Carr. I wrapped brass shim stock around it before chucking it in the lathe to keep the hardened jaws from damaging the teeth. I needed to make a hole suitable for press fitting on a 5mm (0.1969 in) shaft. Generally about .001" to .0015" smaller than the shaft works well. Usually a special sized chucking reamer is required. But not this time! First I used a #10 drill to make a 0.1935 hole. I reamed it out with a #9 (0.1960) drill. This was fine for the press fit. Then I drilled in about .15 inches deep with a #8 (0.1990) drill. This let me slip it on the shaft so it would be straight when the pressure was applied. The last step was to use the cutoff tool to slice off the gear rod to make the new pinion 0.375 long. It worked great. Only moderate pressure was required to force it in the shaft.

I started with a piece of 12 tooth, 32 pitch gear rod from McMaster Carr. I wrapped brass shim stock around it before chucking it in the lathe to keep the hardened jaws from damaging the teeth. I needed to make a hole suitable for press fitting on a 5mm (0.1969 in) shaft. Generally about .001" to .0015" smaller than the shaft works well. Usually a special sized chucking reamer is required. But not this time! First I used a #10 drill to make a 0.1935 hole. I reamed it out with a #9 (0.1960) drill. This was fine for the press fit. Then I drilled in about .15 inches deep with a #8 (0.1990) drill. This let me slip it on the shaft so it would be straight when the pressure was applied. The last step was to use the cutoff tool to slice off the gear rod to make the new pinion 0.375 long. It worked great. Only moderate pressure was required to force it in the shaft.

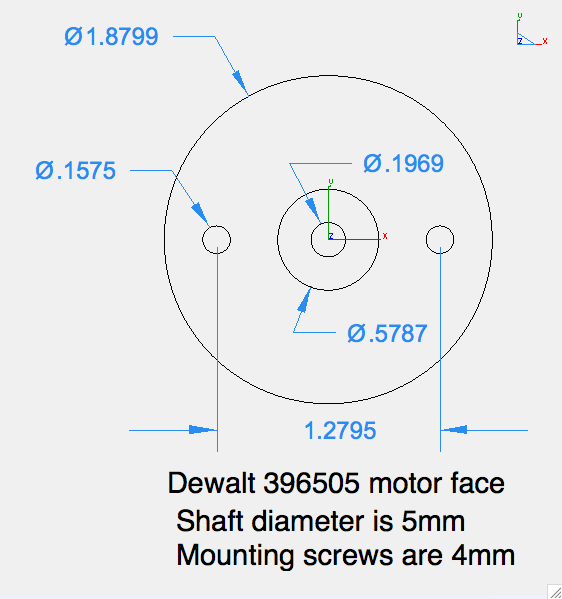

Dimensions taken from the motors I have.

Hit Counter = 55283

Previous page: Arduino Stuff

Next page: 14.4 Volt DrillMaster Modification